In this post, we will guide you through a Wavemaster Jet Pump Repair for your spa. This post may also be referenced for replacing the complete wet end of the pump.

When the shaft seal is leaking, water will be seen dripping from where the shaft of the motor enters the back of the wet end. Often the shaft seal will only leak when the pump is running.

You can watch the Wavemaster Jet Pump Repair How-To video below, or follow the instructions below:

NOTE: This repair requires you to drain the spa.

Tools Needed:

- Standard Phillips Screwdriver

- Standard Flathead Screwdriver

- Socket Wrench

- Locking Needle Nose Pliers (optional)

Click (HERE) to find replacement parts for your Wavemaster Jet Pump

1. Remove the Wavemaster Jet Pump

NOTE: Turn off the power to the spa before following any of these steps.

After shutting off the power to the spa, unplug the power wires of the jet pump from the control box. Next, remove the mounting bolts from the Jet Pump. Lastly, loosen both of the 2″ compression fittings that attach to the wet-end of the pump and remove the pump.

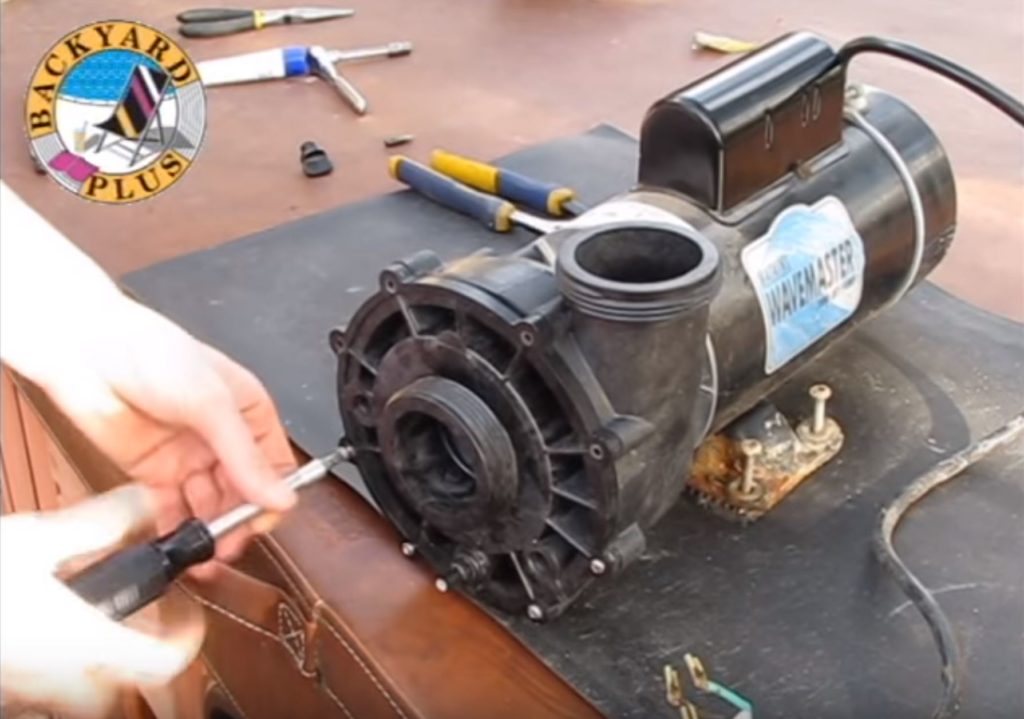

2. Dismantle the Jet Pump Wet End

The first step in taking apart the Wet End Kit is removing the seal plate from the front of the wet end. Simply remove the screws or bolts that hold it in place and separate it from the volute. There are a few different models of wet ends but most are pretty similar to the one you see in the photo above.

Inside the volute, you’ll see the impeller with a wear ring on the end of it. Remove the wear ring and then flip the pump around and remove the rear cover of the motor. This gives you access to the other end of the shaft of the motor.

3. Remove the Impeller

Use a flathead screwdriver to stop the rotation of the shaft while the impeller is unscrewed from the motor shaft. Another way to do it, if there is enough metal surface on the shaft expose between the wet end and the motor, is to clamp a pair of locking needle-nose pliers to restrict the movement of the motor shaft. Remove the impeller by turning it counterclockwise.

4. Remove the Jet Pump Volute

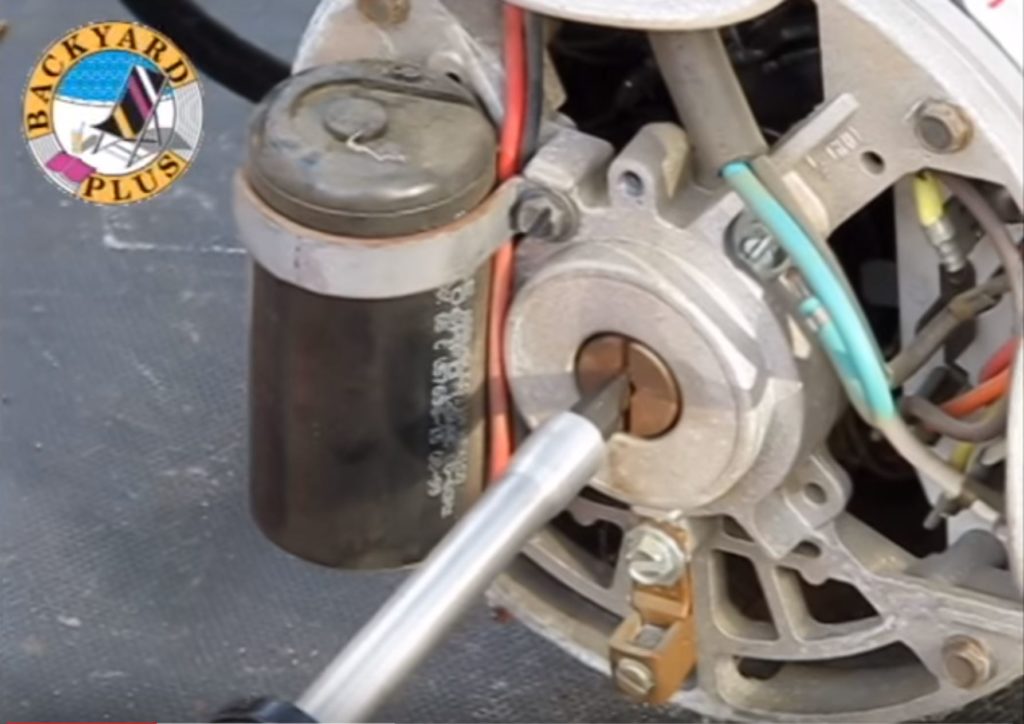

Next, we’re going to remove the pump volute. It’s held on by four bolts which go all the way through the motor. Loosen these four bolts and then pull them out of the motor.

NOTE: Be careful not to touch the terminals on the capacitor with the tool as the capacitor can still retain a charge even if the motor isn’t connected to electricity.

Once all the bolts are removed the Wet-End should easily separate from the motor.

5. Remove the Shaft Seal

The white ceramic half of the seal is pressed into the volute and needs to be removed. The easiest way to get it out is to flip the volute on its face and use a flathead screwdriver to push the ceramic disk from the back to pop it out.

The new seal may come with a black plastic cup around it and the cup is not used for most shaft seals.

Now, you need to clean the shiny surface of the ceramic seal with a paper towel to make sure there are no oils on the surface. The surface should be completely shiny and look like glass when you angle it in the light.

6. Install the New Shaft Seal

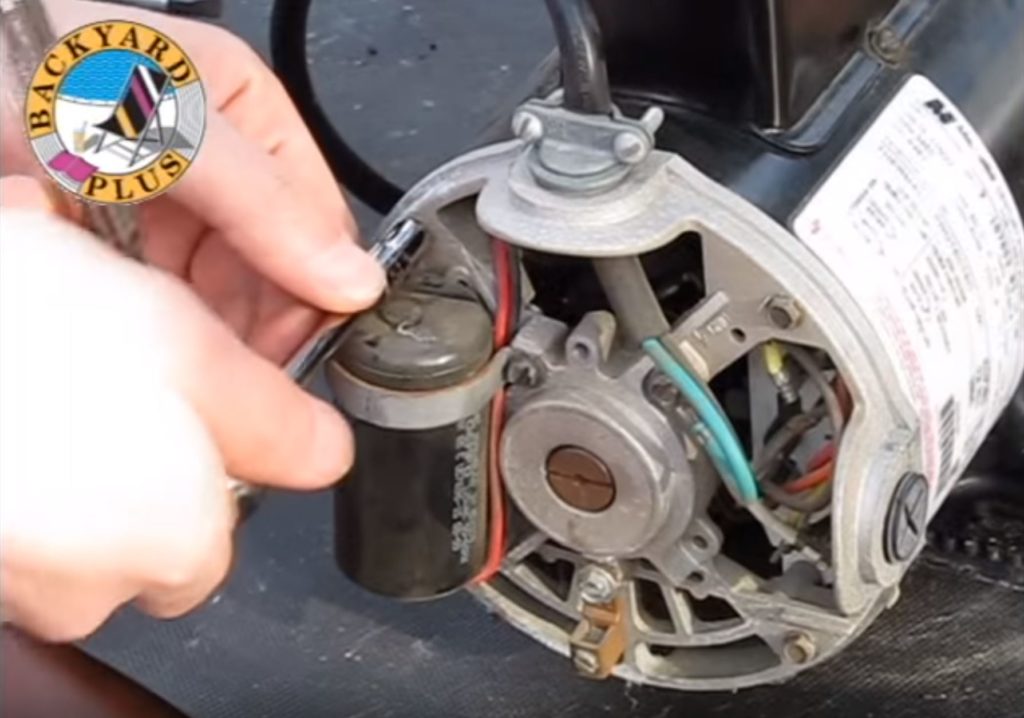

Next, we need to use a socket to press the ceramic seal into the volute.

Set the ceramic seal into the volute and then choose a socket that is slightly smaller than the diameter of the seal. Wrap a paper towel around the end of the socket as you press the seal into the volute to prevent the socket from scratching the ceramic seal.

7. Install the Volute

Now the volute can be reinstalled on the motor. Set the volute on the end of the motor and then install and hand tighten each of the bolts that go through the motor into the legs of the volute. After the bolts are all hand tightened, use a wrench to tighten each of the bolts. Make sure you don’t touch the contacts on the capacitor.

8. Install the Spring Seal and Impeller

Now it’s time to put the other half of the shaft seal on the shaft of the impeller. The old seal simply slides off the impeller stem and the new one slides on. Make sure the end with the rubber o-ring goes towards the impeller and the graphite end is pointed away from the impeller.

After you’ve slid the seal on, make sure you wipe the graphite surface clean with a paper towel.

After this is done we need to stop the shaft of the motor from turning again so we can screw the impeller back on. Secure the motor shaft using locking pliers or by holding a flathead screwdriver in the slot of the shaft of the motor at the end opposite the wet end. Now screw the impeller on clockwise until you feel it cannot tighten further. You should feel the impeller stop turning firmly when it’s fully tightened. Finally, reattach the cover on the back of the motor.

9. Install the Wear Ring

Now place the new wear ring on the impeller with the fatter end of the wear ring positioned away from the larger portion of the impeller.

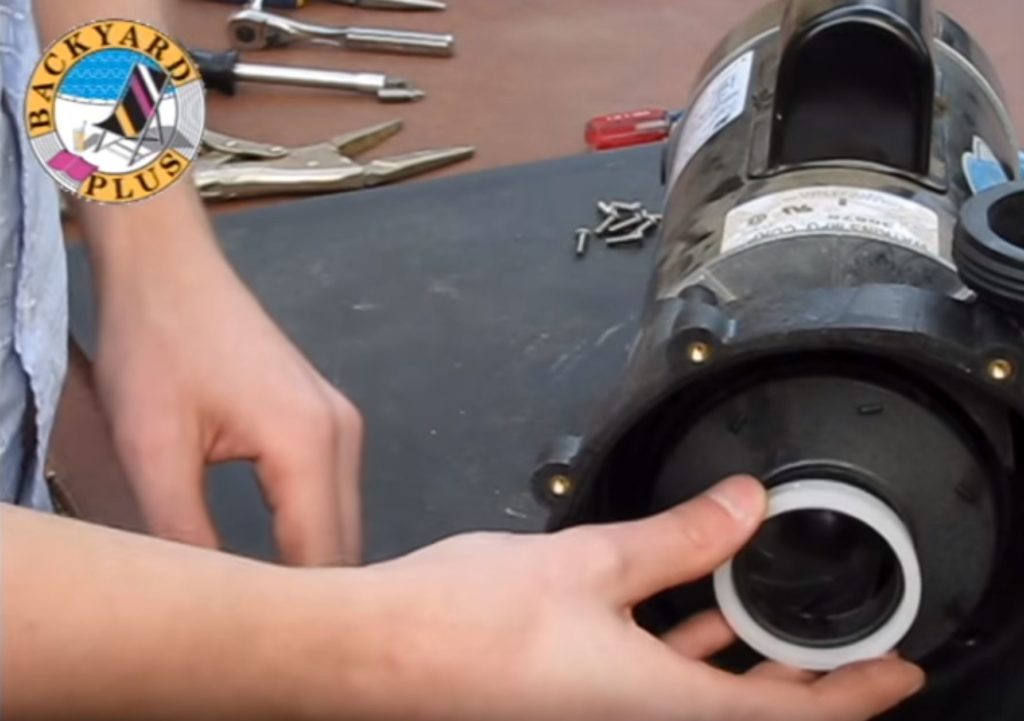

10. Install the Seal Plate

The last step is to reinstall the seal plate. Before installing the o-ring that goes around the seal plate, apply silicone grease to the entire o-ring. Slide the lubricated o-ring onto the outer edge of the seal plate. Once the o-ring is seated on the edge of the seal plate, the seal plate can be pushed back onto the volute.

The seal plate has a notch in it so it can only be installed one way. After the seal plate is pushed back on, reinstall all the screws that hold the plate in place. Tighten all the screws loosely first and then go around tightening each one gradually so the seal plate is tightened evenly. The screws don’t need to be ridiculously tight, but you should see the gap between the volute and the steel plate disappear.

Your Jet Pump is now ready to be reinstalled. After installation, be sure to power on the spa and make sure the Jet Pump is working properly and that there are no leaks.

Featured Products

Congratulations on mastering a Wavemaster Jet Pump Repair!

Backyard Plus is Here to Help You Be the Hero.

Questions about your spa? Contact us! We are the top Hotspring spa parts retailer on the web.

Call us at (805)541-9000

Text us to receive technical support

We offer:

- Our Parts Finder which allows you to find exact-match replacements for your hot tub

- Free technical support that will allow you to maintain and repair your own spa accordingly

- Information regarding your products and their usage through our blog posts.

- Tutorials and assistance through our videos

- Follow us on our Facebook page

Our goal here at Backyard Plus is to help save you money by avoiding costly service calls for repairs that you can easily do yourself!

Thanks for reading Wavemaster Jet Pump Repair (10 Simple Steps)!